Welcome to Alltronix. An ISO 9001:2015

With the Face series, Supfina provides the ultimate solution for versatile flat finishing for medium and large workpiece volumes – fast and flexible.

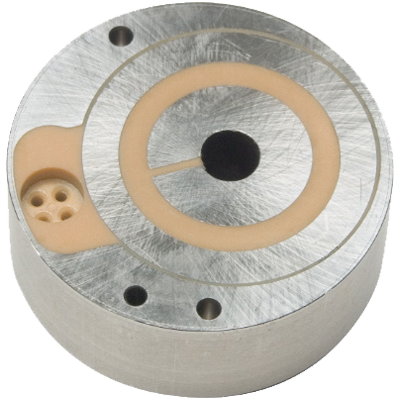

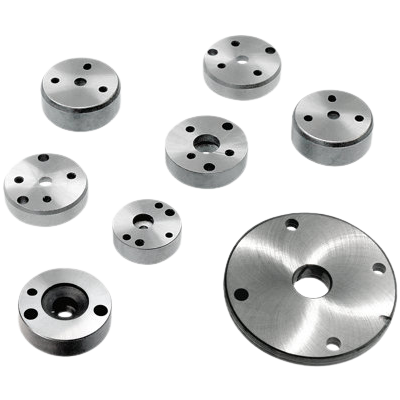

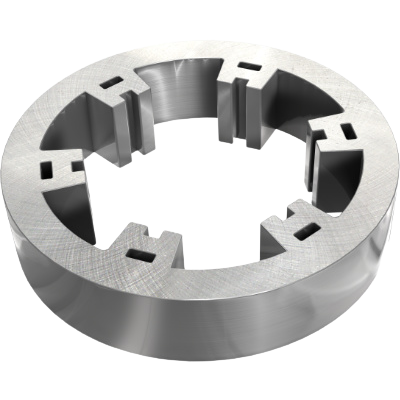

Components from the fields of injection technology, transmission components, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with the highest reliability and efficiency.

The Supfina Nano machine series covers a wide range of flat finish processing needs.

Transmission components, engine parts, components from the fields of injection technology, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with highest reliability and efficiency.

| Technical Data | |

|---|---|

| Workpiece Length | 150 mm |

| Workpiece Diameter | 100 mm |

| Machining Diameter | 50 mm |

| Superfinishing Attachments | 1 – 2 |

| Spindle Speed RPM | 30000 |

| Technical Data | |

|---|---|

| Workpiece Length | Up to 200 mm |

| Workpiece Diameter | Up to 200 mm |

| Machining Diameter | Up to 150 mm |

| Superfinishing Units | Up to 7 |

| Chuck | Up to 8 |

| Process Integration | Flat finishing with cup wheels, brush deburrers, size measurement, tape finishing |

Supfina Face – the new rotary transfer machine generation: a flexible rotary transfer solution with a unique machine structure allowing the highest production volumes while also being flexible for maximum cost efficiency.

The development of the Face series was based on the general standards of: cost efficiency, flexibility, safety and environment.