Welcome to Alltronix. An ISO 9001:2015

The latest generation of the Planet V machine series takes double sided grinding, also known as Double Disk Grinding, to a new level.

The extremely rigid machine bed enables grinding of steel, sintered metal, non-ferrous metal, plastics, ceramics and glass. Two powerful motors achieve stock removal of over 1mm at cycle times well below one second. In just one pass, the workpiece is machined to an average tolerance of +/- 0.003mm.

The vertical spindle arrangement offers the user the highest resulting workpiece qualities while reducing piece costs.

Unique features include the Smart Dressing Cycle, the patented grinding gap visualization and the integrated tool change aid. This reduces downtime as tool changes and retooling operations are kept to a minimum.

Due to its space-saving design, Planet V machines can be easily integrated into new or existing production lines.

With a new generation of Planet V, precision, productivity, and ease of use in Double Disk Grinding have increased once again, with a smaller footprint and reduced costs.

| Workpiece Data | |

|---|---|

| Workpiece Diameter | 6 – 85 mm |

| Workpiece Thickness | 0.6 – 40 mm |

Supfina offers the Planet V7 for larger requirements in Double Disk Grinding.

It includes all the advantages of the Planet V series. Two 64 kW powerful motors allow stock removal of 3mm and up with cycle times of ~37 seconds.

| Workpiece Data | |

|---|---|

| Workpiece Diameter | 10 –180 mm |

| Workpiece Thickness | 1–100 mm |

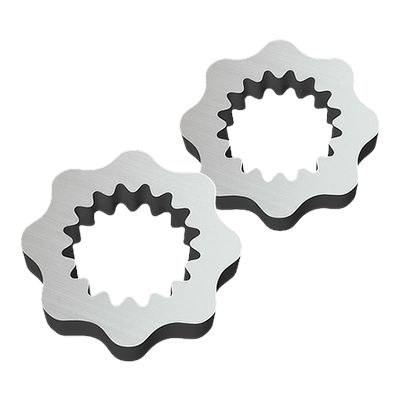

The Planet V machine series has innovative features such as the patented Tilt Navigation for operator-guided adjustment of the grinding gap, the integrated tool change aid and a modular dressing system for grinding wheels.