Welcome to Alltronix. An ISO 9001:2015

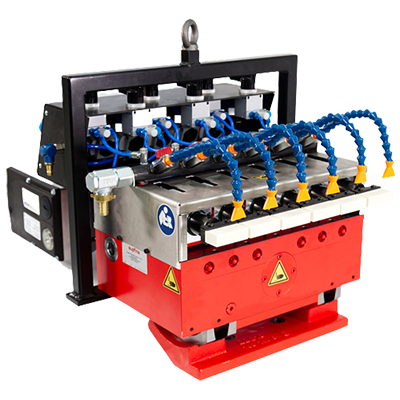

For the highest surface qualities, our superfinishing attachments can be easily attached to your grinding and lathes. In this way, you can offer your customers completely new opportunities along with increasing your competitiveness.

We are happy to advise you and develop concrete processes for your application: from the attachment to the right sanding tape or grinding stones to the exact process parameters.

Thanks to its modular design, the Supfina LCM is the ideal carrier machine for attachments.

Cost-effective prototyping: The flexible machining of crankshafts in small and medium quantities – this is where the Supfina LCM Crank shines.

The LCM TS is specially designed for the highest precision of spherical components such as spherical plain bearings and rod ends. Process reliability and low cycle times ensure cost-efficient production.

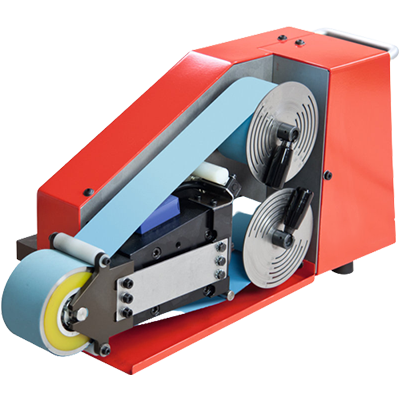

The SpeedFinish technology was developed to combine the advantages of grinding with those of superfinishing; i.e. produce a homogeneous and grinding point-free roughness depth quality in the shortest possible machining time.

Typical workpieces for machining in the Supfina SpeedFinish process: